Shop manual ô tô NISSAN 2000 Xterra - P10

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (1.05 MB, 36 trang )

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

KA24DE

ENGINE LUBRICATION SYSTEM..................................3

Precautions..................................................................3

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

″AIR BAG″

.................................................................3

LIQUID GASKET APPLICATION PROCEDURE

............3

Preparation ..................................................................4

SPECIAL SERVICE TOOLS

........................................4

Lubrication Circuit........................................................5

Oil Pressure Check......................................................6

Oil Pump......................................................................6

REMOVAL AND INSTALLATION

.................................6

REGULATOR VALVE INSPECTION

............................7

OIL FILTER

...............................................................7

OIL PUMP INSPECTION

............................................7

Service Data and Specifications (SDS).......................8

OIL PRESSURE CHECK

............................................8

REGULATOR VALVE

.................................................8

OIL PUMP

.................................................................8

ENGINE COOLING SYSTEM..........................................9

Precautions..................................................................9

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

″AIR BAG″

.................................................................9

LIQUID GASKET APPLICATION PROCEDURE

............9

Preparation ................................................................10

SPECIAL SERVICE TOOLS

......................................10

Cooling Circuit ...........................................................10

System Check............................................................11

CHECKING COOLING SYSTEM HOSES

...................11

CHECKING RADIATOR

............................................11

CHECKING COOLING SYSTEM FOR LEAKS

............11

CHECKING RADIATOR CAP

....................................12

Water Pump...............................................................12

REMOVAL

...............................................................12

INSPECTION

...........................................................12

INSTALLATION

........................................................13

Thermostat.................................................................13

REMOVAL

...............................................................13

INSPECTION

...........................................................13

INSTALLATION

........................................................13

Radiator .....................................................................14

REMOVAL AND INSTALLATION

...............................14

COMPONENTS

.......................................................15

INSPECTION

...........................................................15

Cooling Fan (Crankshaft driven) ...............................16

REMOVAL AND INSTALLATION

...............................16

INSPECTION

...........................................................16

Refilling Engine Coolant............................................16

Overheating Cause Analysis .....................................17

Service Data and Specifications (SDS).....................18

THERMOSTAT

........................................................18

RADIATOR

..............................................................18

VG33E

ENGINE LUBRICATION SYSTEM................................19

Precautions................................................................19

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

″AIR BAG″

...............................................................19

LIQUID GASKET APPLICATION PROCEDURE

..........19

Preparation ................................................................20

SPECIAL SERVICE TOOLS

......................................20

Lubrication Circuit......................................................20

Oil Pressure Check....................................................21

Oil Pump....................................................................21

REMOVAL AND INSTALLATION

...............................21

DISASSEMBLY AND ASSEMBLY

..............................22

INSPECTION

...........................................................23

REGULATOR VALVE INSPECTION

..........................23

OIL FILTER

.............................................................23

OIL FILTER BRACKET

.............................................24

Service Data and Specifications (SDS).....................24

OIL PRESSURE CHECK

..........................................24

REGULATOR VALVE

...............................................24

OIL PUMP

...............................................................24

ENGINE COOLING SYSTEM........................................25

Precautions................................................................25

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

″AIR BAG″

...............................................................25

LIQUID GASKET APPLICATION PROCEDURE

..........25

Preparation ................................................................26

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SPECIAL SERVICE TOOLS

......................................26

Cooling Circuit ...........................................................26

System Check............................................................26

CHECKING COOLING SYSTEM HOSES

...................27

CHECKING RADIATOR CAP

....................................27

CHECKING RADIATOR

............................................27

CHECKING COOLING SYSTEM FOR LEAKS

............27

Water Pump...............................................................28

REMOVAL

...............................................................28

INSPECTION

...........................................................29

INSTALLATION

........................................................29

Thermostat.................................................................29

REMOVAL

...............................................................29

INSPECTION

...........................................................30

INSTALLATION

........................................................30

Radiator .....................................................................31

REMOVAL AND INSTALLATION

...............................31

COMPONENTS

.......................................................31

INSPECTION

...........................................................32

Cooling Fan (Crankshaft driven) ...............................32

REMOVAL AND INSTALLATION

...............................32

INSPECTION

...........................................................32

Refilling Engine Coolant............................................34

Overheating Cause Analysis .....................................34

Service Data and Specifications (SDS).....................35

THERMOSTAT

........................................................35

RADIATOR

..............................................................35

CONTENTS

(Cont’d)

LC-2

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) “AIR BAG”

NGLC0066

The Supplemental Restraint System “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a seat

belt, helps to reduce the risk or severity of injury to the driver and front passenger in certain types collisions.

The Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel),

a front passenger air bag module (located on the instrument panel on the passenger side), seat belt pre-

tensioners, a diagnosis sensor unit, a crash zone sensor (4WD models), a warning lamp, wiring harness, and

spiral cable.

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

¼ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

¼ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, refer to RS-16.

¼ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses (except “SEAT BEAT PRE-TENSIONER”) cov-

ered with yellow insulation either just before the harness connectors or on the complete harness,

are related to the SRS.

SEM164F

AEM080

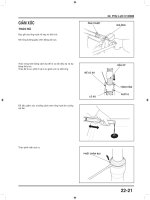

LIQUID GASKET APPLICATION PROCEDURE

NGLC0067

1. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine RTV Silicone Sealant Part No. 999 MP-A7007

or equivalent.)

¼ For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

¼ For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEM

KA24DE

Precautions

LC-3

Preparation

SPECIAL SERVICE TOOLS

=NGLC0068

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

(J34301-C)

Oil pressure gauge set

1: (J34301-1)

Oil pressure gauge

2: (J34301-2)

Hoses

3: (J34298)

Adapter

4: (J34282-1)

Adapter

5: (790-301-1230-A)

60° adapter

6: (J34301-15)

Square socket

AAT896

Measuring oil pressure

Maximum measuring range:

1,379 kPa (14 kg/cm

2

, 200 psi)

WS39930000

( — )

Tube presser

NT052

Pressing the tube of liquid gasket

KV10115801

(J38956)

Oil filter wrench

NT362

Removing oil filter

ENGINE LUBRICATION SYSTEM

KA24DE

Preparation

LC-4

Lubrication Circuit

NGLC0069

ALC116

1. Connecting rod

2. Connecting rod bearing

3. Main bearing

4. Oil filter

5. Oil strainer

6. Oil pump

7. Oil pan

8. Piston oil jet

9. Timing chain tensioner

10. Idler sprocket

11. Upper timing chain tensioner

12. Exhaust camshaft

13. Intake camshaft

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEM

KA24DE

Lubrication Circuit

LC-5

ALC059

Oil Pressure Check

NGLC0070

WARNING:

¼ Be careful not to burn yourself, as the engine and oil may

be hot.

¼ For M/T models, put gearshift lever in Neutral “N” posi-

tion. For A/T models, put selector lever in Park “P” posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed Approximate discharge pressure

Idle speed More than 78 kPa (0.8 kg/cm

2

, 11 psi)

3,000 rpm 412 - 481 kPa (4.2 - 4.9 kg/cm

2

,60-

70 psi)

¼ If difference is extreme, check oil passage and oil pump

for oil leaks.

6. Install oil pressure switch with sealant.

: 12.25 – 17.15 N·m (1.3 – 1.7 kg-m, 9 – 12 ft-lb)

Oil Pump

REMOVAL AND INSTALLATION

NGLC0071

SLC945-A

ENGINE LUBRICATION SYSTEM

KA24DE

Oil Pressure Check

LC-6

ALC054

¼ Always replace with new oil seal and gasket.

¼ When removing oil pump, turn crankshaft so that No. 1

piston is at TDC on its compression stroke.

¼ When installing oil pump, apply engine oil to gears, then

align punchmark on drive spindle and oil hole on oil

pump.

ALC058

REGULATOR VALVE INSPECTION

NGLC0072

1. Visually inspect components for wear and damage.

2. Check oil pressure regulator valve sliding surface and valve

spring.

3. Coat regulator valve with engine oil. Check that it falls

smoothly into the valve hole by its own weight.

¼ Replace regulator valve set or oil pump assembly, if dam-

aged.

ALC124

OIL FILTER

NGLC0073

The oil filter is a small, full-flow cartridge type and is provided with

a relief valve.

¼ The new and previous oil filter designs differ from each

other and are not interchangeable.

¼ Use Tool KV10115801 (J38956) for removing oil filter.

SLC026

SLC732

OIL PUMP INSPECTION

NGLC0074

Using a feeler gauge, check the following clearances.

Standard clearance:

Unit: mm (in)

Rotor tip clearance 1 Less than 0.12 (0.0047)

Outer rotor to body clearance 2 0.15 - 0.21 (0.0059 - 0.0083)

Side clearance (with gasket) 3 0.04 - 0.100 (0.0016 - 0.0039)

¼ If the tip clearance (1) exceeds the limit, replace gear set.

¼ If body to gear clearances (2, 3) exceed the limit, replace

oil pump assembly.

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEM

KA24DE

Oil Pump (Cont’d)

LC-7

Service Data and Specifications (SDS)

OIL PRESSURE CHECK

NGLC0075

Engine speed Approximate discharge pressure

Idle speed More than 78 kPa (0.8 kg/cm

2

, 11 psi)

3,000 rpm 412 - 481 kPa (4.2 - 4.9 kg/cm

2

, 60 - 70 psi)

REGULATOR VALVE

NGLC0131

Unit: mm (in)

Regulator valve to oil pump cover clearance 0.040 - 0.097 (0.0016 - 0.0038)

OIL PUMP

NGLC0076

Unit: mm (in)

Rotor tip clearance Less than 0.12 (0.0047)

Outer rotor to body clearance 0.15 - 0.21 (0.0059 - 0.0083)

Side clearance (with gasket) 0.04 - 0.100 (0.0016 - 0.0039)

ENGINE LUBRICATION SYSTEM

KA24DE

Service Data and Specifications (SDS)

LC-8

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) “AIR BAG”

NGLC0133

The Supplemental Restraint System “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a seat

belt, helps to reduce the risk or severity of injury to the driver and front passenger in certain types collisions.

The Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel),

a front passenger air bag module (located on the instrument panel on the passenger side), seat belt pre-

tensioners, a diagnosis sensor unit, a crash zone sensor (4WD models), a warning lamp, wiring harness, and

spiral cable.

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

¼ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

¼ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, refer to RS-16.

¼ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses (except “SEAT BEAT PRE-TENSIONER”) cov-

ered with yellow insulation either just before the harness connectors or on the complete harness,

are related to the SRS.

SEM164F

AEM080

LIQUID GASKET APPLICATION PROCEDURE

NGLC0109

1. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine RTV Silicone Sealant Part No. 999 MP-A7007

or equivalent.)

¼ For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

¼ For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

KA24DE

Precautions

LC-9

Preparation

SPECIAL SERVICE TOOLS

=NGLC0110

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

EG17650301

(J33984-A)

Radiator cap tester

adapter

NT564

Adapting radiator cap tester to radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

WS39930000

( — )

Tube presser

NT052

Pressing the tube of liquid gasket

Cooling Circuit

NGLC0111

ALC117

ENGINE COOLING SYSTEM

KA24DE

Preparation

LC-10

System Check

NGLC0112

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

Wrap a thick cloth around the radiator cap. Slowly turn it a

quarter turn to allow built-up pressure to escape. Carefully

remove the radiator cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

NGLC0112S01

Check hoses for the following:

¼ Improper attachment

¼ Leaks

¼ Cracks

¼ Damage

¼ Chafing

¼ Deterioration

CHECKING RADIATOR

NGLC0112S02

Check radiator for mud or clogging. If necessary, clean radiator as

follows.

¼ Be careful not to bend or damage the radiator fins.

¼ When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, radiator shroud and horns.

¼ Tape the harness connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core ver-

tically downward.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing when stains no longer flow out from the radia-

tor.

4. Blow air into the back side of radiator core vertically downward.

¼ Use compressed air lower than 490 kPa (5 kg/cm

2

, 71 psi) and

keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

SLC756A

CHECKING COOLING SYSTEM FOR LEAKS

NGLC0112S03

To check for leakage, apply pressure to the cooling system with a

radiator cap tester.

Testing pressure:

157 kPa (1.6 kg/cm

2

, 23 psi)

CAUTION:

Higher pressure than specified may cause radiator damage.

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

KA24DE

System Check

LC-11

SLC755A

CHECKING RADIATOR CAP

NGLC0112S04

To check radiator cap, apply pressure to radiator cap with a radia-

tor cap tester.

Radiator cap relief pressure:

Standard

78 - 98 kPa (0.8 - 1.0 kg/cm

2

, 11 - 14 psi)

Limit

59 - 98 kPa (0.6 - 1.0 kg/cm

2

,9-14psi)

SMA967B

Pull the negative pressure valve to open it.

Check that it closes completely when released.

ALC077

Water Pump

REMOVAL

NGLC0113

CAUTION:

¼ When removing water pump assembly, be careful not to

get coolant on drive belts.

¼ Water pump cannot be disassembled and should be

replaced as a unit.

¼ After installing water pump, connect hose and clamp

securely. Check for leaks using radiator cap tester.

1. Drain coolant from engine.

Refer to MA-18 (“Changing Engine Coolant”, “ENGINE MAIN-

TENANCE”).

2. Remove fan coupling with fan.

3. Remove power steering pump drive belt, generator drive belt

and A/C compressor drive belt.

4. Remove water pump.

SLC738

INSPECTION

NGLC0114

¼ Check body assembly for rust or corrosion.

¼ Check for rough operation due to excessive end play.

ENGINE COOLING SYSTEM

KA24DE

System Check (Cont’d)

LC-12

SLC188A

INSTALLATION

NGLC0115

1. Use a scraper to remove liquid gasket from water pump.

¼ Also remove traces of liquid gasket from mating surface

of cylinder block.

ALC078

2. Apply a continuous bead of liquid gasket to mating surface of

water pump.

¼ Use Genuine RTV Silicone Sealant Part No. 999 MP-A7007

or equivalent.

When filling radiator with coolant, refer to MA-18 (“Changing

Engine Coolant”, “ENGINE MAINTENANCE”).

When installing drive belts, refer to MA-17 (“Checking Drive

Belts”).

ALC087

Thermostat

REMOVAL

NGLC0116

¼ Be careful not to spill coolant over engine compartment.

Use a rag to absorb coolant.

1. Drain coolant from engine. Refer to MA-18 (“Changing Engine

Coolant”, “ENGINE MAINTENANCE”).

2. Remove air cleaner and air duct assembly.

3. Remove water hose from water inlet housing.

4. Remove water inlet housing, then take out thermostat.

SLC343

INSPECTION

NGLC0117

1. Check valve seating condition at normal room temperature. It

should seat tightly.

2. Check valve opening temperature and valve lift.

Valve opening temperature 76.5°C (170°F)

Valve lift More than 8 mm/90°C (0.31 in/194°F)

3. Check if valve closes at 5°C(9°F) below valve opening

temperature.

ALC088

INSTALLATION

NGLC0118

1. Use a scraper to remove old liquid gasket from water inlet.

¼ Also remove traces of liquid gasket from mating surface

of front cover.

2. Apply a continuous bead of liquid gasket to mating surface of

water inlet.

¼ Use Genuine RTV Silicone Sealant Part No. 999 MP-A7007

or equivalent.

GI

MA

EM

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

KA24DE

Water Pump (Cont’d)

LC-13

SLC097

3. Install thermostat with jiggle valve or air bleeder at upper side.

4. Install water inlet housing.

5. Install water hose to water inlet housing.

6. Install air cleaner and air duct assembly.

7. Refill engine coolant. Refer to MA-18 (“Changing Engine

Coolant”, “ENGINE MAINTENANCE”).

¼ After installation, run engine for a few minutes and check

for leaks.

Radiator

REMOVAL AND INSTALLATION

NGLC0119

1. Remove under cover.

2. Drain coolant from radiator. Refer to MA-18 (“Changing Engine

Coolant”, “ENGINE MAINTENANCE”).

3. Disconnect upper and lower radiator hoses.

4. Remove air cleaner and air duct assembly.

5. Remove lower radiator shroud.

6. Remove radiator shroud.

7. Remove A/T oil cooler hoses (A/T models only).

8. Disconnect coolant reservoir hose.

9. Remove radiator.

10. After replacing radiator, install all parts in reverse order of

removal.

11. Refill engine coolant. Refer to MA-18 (“Changing Engine

Coolant”, “ENGINE MAINTENANCE”).

¼ After installation, run engine for a few minutes, and check

for leaks.

ENGINE COOLING SYSTEM

KA24DE

Thermostat (Cont’d)

LC-14