Quy trình hàn tàu VINASHIN

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (479.17 KB, 10 trang )

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 2

APPLICATION OF WELDING AT ERECTION

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 3

ORD. FRAME SECTION

FB125x12

#9

#1

S=9

#3

#2

#4

#5

#6

#8

#7

FB125x12

FB125x12

#10

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 4

BOX FRAME SECTION

2 SETS FOR EACH HOLD

#2

#1

10

#4

#3

#6

#5

11

#9

11

#8

#7

#10

10

S = 11

S = 11

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 5

W.T. BHD. SECTION

#7

#8

#9

#10

S=11

#4

#5

#6

#1

#2

S=11

#3

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 6

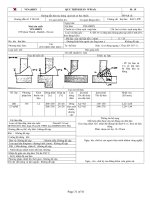

2 SMAW Edge preparation for Butt joint .

t

2

− t

1

≤ 3

t

2

- t

1

> 3

t

1

<6

6.5 <t

1

≤ 40

6.5 <t

1

≤ 40

t

1

> 25

t

1

≥ 6

t

2

- t

1

≤ 3

Misalignment 0~2

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 7

2 SMAW Edge preparation for fillet joint .

Range Edge preparation Remarks

E: Actual leg length

3

0

0

+

−

=

G

E = Rule leg length + (G-2)

θ° ≥ 60°

and

C < 2

5

0

0

+

−

=

G

E = Rule leg length + (G-2)

θ° ≥ 60°

and

C ≥ 2

5

0

0

+

−

=

G

E = Rule leg length + (G-2)

75°≤ θ° ≤ 90°

5

0

0

+

−

=

G

5

0

0

+

−

=

G

E = Rule leg length + (G-2)

3 CO

2

Edge preparation for Butt joint

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 8

t

2

− t

1

≤ 3

t

2

- t

1

> 3

2.4 ≤ t

1

≤ 6

6 < t

1

≤ 40

6 <t

1

≤ 40

t

1

> 25

t

1

≥ 6

t

2

- t

1

≤ 3

Misalignment 0~2

3 CO

2

Edge preparation for fillet joint

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 9

Range Edge preparation Remarks

E: Actual leg length

3

0

0

+

−

=

G

E = Rule leg length + (G-2)

5

0

0

+

−

=

G

E = Rule leg length + (G-2)

θ° ≥ 60°

and

C ≥ 2

t ≤ 10 t > 10

5

0

0

+

−

=

G

E = Rule leg length + (G-2)

45° ≤ θ° < 60°

t ≤ 10 t > 10

5

0

0

+

−

=

G

E = Rule leg length + (G-2)

θ° < 45°

5

0

0

+

−

=

G

E = Rule length

75°≤ θ° ≤ 90°

4 CO 2 ONE SIDE

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 10

5 CO 2 + SAW

t

2

− t

1

≤ 3

t

2

- t

1

> 3

6 <t

1

≤ 40

WELDING APPLICATION PLAN

Date : 10-9-2004

Procedure No :

H210-WP-PL

Page : 11

6 SAW Edge preparation for fillet joint .

Place thickness

Unit: mm

t

2

− t

1

≤ 3

t

2

- t

1

> 3

3.2 ≤ t

1

< 14

14 ≤ t

1

≤ 20

20 < t

1

≤ 40

Misalignment 0~2

Place

thickness

M R

O

O

1

O

O

2

20 < t

≤ 23 5 ± 1 8 ± 1 70

O

± 2

O

90

O

± 2

O

23 < t

≤ 30 9 ± 1 9 ± 1 60

O

± 2

O

90

O

± 2

O

30 < t

≤ 35 10 ± 1 10 ± 1 50

O

± 2

O

90

O

± 2

O

35 < t

≤ 40 1 ± 1 11 ± 1 50

O

± 2

O

90

O

± 2

O

40 < t

≤ 50 15 ± 1 11 ± 1 45

O

± 2

O

90

O

± 2

O