Machine Design Databook Episode 1 part 5 pot

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (2.02 MB, 40 trang )

FIGURE 4-22 Reproduced with permission. Stress-concentration factor K

for notched flat bar in tension. (R. E. Peterson,

‘‘Design Factors for Stress Concentration,’’ Machine Design, Vol. 23, Nos. 2 to 7, 1951.)

(iii) Bar with shallow V-groove in tension for

r

h

1

> 1

(iv) Elliptical groove at the edge of plate in

tension

(v) Bar with symmetrical U, semicircular

shallow grooves in bending (Fig. 4-23).

K

v

¼ 1 þðK

v

À 1Þ 1 À

À

180 À

1 þ2:4

ffiffiffiffiffiffiffi

r=h

1

p

()

ð4-25Þ

K

¼ 1 þ

2h

1

b

ð4-26aÞ

K

¼ 1 þ2

ffiffiffiffiffi

h

1

r

r

ð4-26bÞ

K

¼ 1 þ

1

4:27

D

d

À 4

h

1

r

2

4

3

5

0:85

ð4-27aÞ

or

K

¼ 1 þ

D

d

À 1

2

4:27

D

d

À 4

d

r

2

6

6

6

4

3

7

7

7

5

0:85

ð4-27bÞ

Stress concentration factor theoretical/empirical

or otherwise

Particular Extreme value Formula

4.14 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

FIGURE 4-23 Reproduced with permission. Stress-con-

centration factor K

for notched flat bar in bending. (R. E.

Peterson, ‘‘Design Factors for Stress Concentration,’’

Machine Design, Vol. 23, Nos. 2 to 7, 1951.)

For stress-concentration factors for small grooves

in a shaft subjected to torsion.

(o) Bar containing shoulders

(i) Bar with shoulders in tension (Fig. 4-24)

TABLE 4-4

Stress-concentration factors for relatively small

grooves in a shaft subject to torsion, K

h

1

r

Included angle of V,deg0.51352

0 1.85 2.01 2.66 3.23 4.54

60 1.84 2.00 2.54 3.06 3.99

90 1.81 1.95 2.40 2.40 3.12

120 1.66 1.75 1.95 2.00 2.13

FIGURE 4-24 Reproduced with permission. Stress-con-

centration factor K

for filleted flat bar in tension. (R. E.

Peterson, ‘‘Design Factors for Stress Concentration,’’

Machine Design, Vol. 23, Nos. 2–7, 1951.)

Refer to Table 4-4.

K

¼ 1 þ

1

2:8

D

d

À 2

h

1

r

2

4

3

5

0:85

ð4-28aÞ

or

K

¼ 1 þ

D

d

À 1

2

2:8

D

d

À 2

d

r

2

6

6

6

4

3

7

7

7

5

0:85

ð4-28bÞ

Stress concentration factor theoretical/empirical

or otherwise

Particular Extreme value Formula

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

4.15

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

(ii) Bar with shoulders in bending (Fig. 4-25)

(p) Press-fitted or shrink-fitted members (Table 4-5):

(i) Plain member

(ii) Grooved member

(iii) Plain member

(iv) Grooved member

(q) Bolts and nuts (Tables 4-6 and 4-7)

Bolt and nut of standard proportions

Bolt and nut having lip

FIGURE 4-25 Reproduced with permission. Stress-concentration factor K

for stepped bar in bending. (R. E. Peterson,

‘‘Design Factors for Stress Concentration,’’ Machine Design, Vol. 23, Nos. 2 to 7, 1951.)

K

¼ 1 þ

1

5:37

D

d

À 4:8

h

1

r

2

4

3

5

0:85

ð4-29aÞ

or

K

¼ 1 þ

D

d

À 1

2

5:37

D

d

À 4:8

d

r

2

6

6

6

4

3

7

7

7

5

0:85

ð4-29bÞ

K

¼ 1:95

K

¼ 1:34

K

f

¼ 2:00

K

f

¼ 1:70

K

¼ 3:85

K

¼ 3:00

TABLE 4-5

Stress-concentration factors in shrink-fitted members

Particular K

K

f

Plain 1.95 2.00

Grooved 1.34 1.70

Stress concentration factor theoretical/empirical

or otherwise

Particular Extreme value Formula

4.16 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

TABLE 4-6

Stress-concentration factors for screw threads

Analysis

Types of thread Seely and Smith Black (8) Peterson (1) Suggested value

Square 2.0

Sharp V 3.0

Whitworth 2.0 3.35 5 to 6

US standard

Medium

Carbon steel 2.5

National coarse thread

Heat-treated 2.84

Nickel steel 3.85

TABLE 4-7

Stress-concentration factors K

f

for screw threads

Annealed Hardened

Type of thread Rolled Cut Rolled Cut

Sellers, American

National, square thread

2.2 2.8 3.0 3.8

Whitworth rounded roots 1.4 1.8 2.6 3.3

TABLE 4-8

Stress-concentration factors for welds

Location K

End or parallel fillet weld 2.7

Reinforced butt 1.2

Tee of transverse fillet weld 1.5

T-butt weld with sharp corners 2.0

TABLE 4-9

Index of sensitivity for repeated stress

Average index of sensitivity q

Material Annealed or soft

Heat-treated and drawn

at 921 K (6488C)

Heat-treated and drawn

at 755 K (4828C)

Armco iron, 0.02% C 0.15–0.20

Carbon steel

0.10% C 0.05–0.10

0.20% C (also cast steel) 0.10

0.30% C 0.18 0.35 0.45

0.50% C 0.26 0.40 0.50

0.85% C 0.45 0.57

Spring steel, 0.56% C, 2.3 Si, rolled 0.38

SAE 3140, 0.73 C; 0.6 Cr; 1.3 Ni. 0.25 0.45

Cr–Ni steel 0.8 Cr; 3.5 Ni 0.25 0.70

Stainless steel, 0.3 C; 8.3 Cr, 19.7 Ni 0.16

Cast iron 0–0.05

Copper, electrolitic 0.07

Duraluminum 0.05–0.13

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

4.17

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

(r) Crane hook:

For crane hook under tensile load

(s) Rotating disk:

For rotating disk with a hole for

R

i

R

o

! 0

For thin disk (ring)

(t) Eye bar:

For eye bar subjected to tensile load

Stress concentration factors for welds

(u) Notch sensitivity factors (Table 4 -9):

(i) Notch sensitivity factor for normal stress

For index of sensitivity for repeated stresses.

(ii) Fatigue stress concentration factor for

normal stress

(iii) Notch sensitivity factor for shear stress

(iv) Fatigue stress-concentration factor for shear

stress

STRESS CONCENTRATION IN FLANGED PIPE

SUBJECTED TO AXIAL EXTERNAL FORCE

The stress in the pipe due to external load F (Fig.

4-25A)

FIGURE 4-25A Pipe and flange under the axial force F

K

¼ 1:56

K

¼ 2

K

¼ 1

K

¼ 2:8

Refer to Table 4-8.

q

¼

K

f

À 1

K

À 1

ð4-30aÞ

q

¼

K

f

À 1

K

0

À 1

ð4-30bÞ

Refer to Table 4-9.

K

f

¼ 1 þq

ðK

À 1Þð4-31aÞ

K

f

¼ 1 þq

ðK

0

À 1Þð4-31bÞ

q

¼

K

f

À 1

K

À 1

ð4-32Þ

K

f

¼ 1 þq

ðK

À 1Þð4-33Þ

¼

f

þ

F

A

ð4-33aÞ

where

f

¼ depends on the distance x from the

flange of the pipe, MPa (psi)

fm

¼ maximum stress at x ¼ 0, MPa (psi)

A ¼ area of the cross section of pipe, m

2

(in

2

)

F ¼ external load, kN (lbf)

Stress concentration factor theoretical/empirical

or otherwise

Particular Extreme value Formula

4.18 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

The value of constant

For plot of the stress ratio

f

fm

versus x

FIGURE 4-25B Stress concentration region in flanged pipe under axial external force F.

Courtesy: Douglas C. Greenwood, Engineering Data for Product Design, McGraw-Hill Publishing Company, New York, 1961.

¼ 10

4

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

3ð1 À

2

Þ

R

2

h

2

s

ð4-33bÞ

where 2R ¼ 2R

i

þ h ¼

mean diameter of pipe, m (in)

2R

o

¼ outer diameter of pipe, m (in)

2R

i

¼ inner diameter of pipe, m (in)

h ¼ thickness of pipe, m (in)

¼ Poisson’s ratio of material

Refer to Fig. 4-25B.

Particular Formula

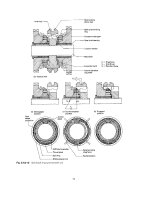

REDUCTION OR MITIGATION OF STRESS CONCENTRATIONS

In designing a machine part, one has to take into consideration the stress concentration occurring in such parts and

eliminate or reduce stress concentration. Fig. 4-25C shows various methods used to reduce stress concentration.

Stream line flowing analogy in a channel can be applied to force flow lines of a flat plate without any type of flow

subject to uniform uniaxial tensile stress as shown in Fig. 4-25C i(a). The stream line flow of water or any fluid is

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS 4.19

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

smooth and straight as shown in Fig. 4-25C i(a). If there is any obstruction such as a heavy iron ball or a pipe or

stone boulder in the path of flow of water, the flow of water or fluid will not be smooth and straight as shown in

Fig. 4-25C i(e). Similarly the force flow lines will not be straight as in case of plate with a circular or elliptical or any

shape of holes in a plate as shown in Figs. 4-25C i(b), i(c), i(d) and i( f ). By providing some geometric changes,

abrupt change of force-flow lines are smoothened. Fatigue strength of parts with stress raiser can be increased

by cold working operation such as shot peening or pressing by balls which creates a nature of stress in thin

layers of the part just opposite to the one induced in it. Press fit stress concentration can be reduced by making

the gripping portion conical in case of hardening steel parts. Nitriding and plating the parts eliminate the corrosion

effect, which combined with stress concentration reduces the fatigue strength of the machine part.

(i) Plates:

4.20 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

(ii) Stepped shafts subject to tensile force:

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS 4.21

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

(iii) Shafts with narrow collar, cylindrical holes and grooves subject to tensile force:

(iv) Shafts subject to bending and torque:

4.22 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

(v) Screws and nuts under torque:

(vi) Keyways in shafts subject to torque:

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS 4.23

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

(vii) Gears:

Stress concentration at fillet and at point of contact are shown in photoelastic fringe pattern and also in Fig. c.The

stress concentration at fillet can be reduced by providing suitable large fillet radius.

Source: From the photoelastic work of K. Lingaiah, Fringe Pattern of Gear-Teeth Showing Stress Concentration at

Root and Contact Point, Department of Mechanical Engineering, University Visvesvaraya College of Engineering,

Bangalore University, Bangalore, 1973.

(viii) Flate plate with and without asymmetrically reinforced circular cutout subjected to uniform uniaxial stress:

FIGURE 4-25C Mitigation of stress concentration in machine members.

s

h

(

a

)

Forces acting on a Gear Tooth Profile

due to Normal Force F

n

b

F

θ

F

n

F

r

ρ

t

Maximum Fringe order

(c)

Maximum Fringe

order means

maximum stress at

point of contact

Tension side of root

fillet with less stress

concentration

Compression side of root fillet gear

tooth with more fringes compare to

tension side root fillet stress analysis

of gear teeth in contact under load

showing photoelastic fringes by using

the results of photoelastic experiment

ρ

t

β

α

α

Fringe pattern of gear teeth

in contact showing stress

concentration at root and point

of contract

(b)

4.24 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

STRESS INTENSITY FACTOR OR

FRACTURE TOUGHNESS FACTOR

The energy criterion approach in the fracture

mechanics analysis:

The energy release rate in case of a crack of length 2a

in an infinite plate subject to tensile stress at infinity

(Fig. 4-26A).

The energy release rate is defined as the rate of change

in potential energy with crack area for a linear elastic

material.

The critical energy release rate.

FIGURE 4-26A A flat infinite plate with a through thickness crack subject to tensile stress at infinity.

The stress intensity factor for a centrally located

straight crack in an infinite plate subjected to uniform

uniaxial tensile stress perpendicular to the plane of

the crack.

The definition and unit of critical stress intensity

factor K

Ic

.

The relation between K

I

and G.

G ¼

2

a

E

ð4-34aÞ

where G ¼ energy release rate

E ¼ modulus of elasticity, GPa (psi)

a ¼ half crack length, mm (in)

G

c

¼

2

f

a

c

E

ð4-34bÞ

where

f

¼ failure stress, MPa (psi)

G

c

¼ material resistance to fracture or

critical fracture toughness

K

I

¼

ffiffiffi

p

ffiffiffi

a

p

ð4-34cÞ

K

Ic

is the critical stress intensity factor for static

loading and plane-strain conditions of maximum con-

straints and is also referred to as the fracture tough-

ness factor of the material at the onset of rapid

fracture and has dimension of (stress

ffiffiffiffiffiffiffiffiffiffiffiffiffi

length

p

), i.e.

MPa

ffiffiffiffi

m

p

(kpsi

ffiffiffiffi

in

p

).

G ¼

K

I

E

ð4-34dÞ

Particular Formula

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

4.25

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

Three modes of loading to analyse stress

fields in cracks:

FIGURE 4-26B Three modes of loading for deformation of crack tip.

First mode of loading and stress components

at crack tip, Fig. 4-26B (a):

The localized stress components at the vicinity of the

‘‘opening mode’’ or ‘‘mode I’’ crack tip in a flat plate

subjected to uniform applied stress at infinity from

the theory of fracture mechanics (Fig. 4-26C).

The crack tip displacement fields for ‘‘first mode’’

(Mode I) in case of linear elastic, isotropic materials.

FIGURE 4-26C State of stress in the vicinity of a crack tip.

x

¼

K

I

ffiffiffiffiffiffiffi

2r

p

cos

2

1 À sin

2

sin

3

2

ð4-35aÞ

y

¼

K

I

ffiffiffiffiffiffiffi

2r

p

cos

2

1 þ sin

2

sin

3

2

ð4-35bÞ

z

¼ ð

x

þ

y

Þ for plane strain ð4-35cÞ

¼ 0 for plane stress ð4-35dÞ

xy

¼

K

I

ffiffiffiffiffiffiffi

2r

p

cos

2

sin

2

cos

3

2

ð4-35eÞ

u

x

¼

K

I

2G

ffiffiffiffiffiffi

r

2

r

cos

2

À 1 þ2 sin

2

2

ð4-35f Þ

u

y

¼

K

I

2G

ffiffiffiffiffiffi

r

2

r

sin

2

þ 1 À2 cos

2

2

ð4-35gÞ

where G ¼ modulus of shear, GPa (psi)

¼ 3 À4 for plane strain

¼ð3 ÀÞ=ð1 þÞ for plane stress

Particular Formula

4.26 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

Second mode of loading and stress

components in the vicinity of crack tip,

Fig. 4-26B (b):

The localized stress components at the vicinity of the

‘‘second mode’’ or ‘‘sliding mode’’ crack tip in a flat

plate subjected to in-plane shear, Fig. 4-26B (b).

The crack tip displacement fields for the ‘‘second

mode’’ (Mode II) in case of linear elastic, isotropic

materials.

Third mode of loading and stress components

in the vicinity of crack tip, Fig. 4-26B (c):

The localized stress components at the vicinity of the

‘‘third mode’’ or ‘‘tearing mode III’’ crack tip in a flat

plate subjected to out-of-plane shear, Fig. 4-26B (c),

in case of linear elastic, isotropic materials.

The crack tip displacement field for the ‘‘third mode’’

(Mode III) in case of linear elastic, isotropic materials.

Stress intensity factor:

The stress intensity factor for a center cracked tension

plate (CCT), according to Fedderson (Fig. 4-27a).

The stress intensity factor for a double edge cracked

plate according to Keer and Freedman (Fig. 4-27b).

x

¼À

K

II

ffiffiffiffiffiffiffi

2r

p

sin

2

2 þ cos

2

cos

3

2

ð4-35hÞ

y

¼

K

II

ffiffiffiffiffiffiffi

2r

p

sin

2

cos

2

cos

3

2

ð4-35iÞ

xy

¼

K

II

ffiffiffiffiffiffiffi

2r

p

cos

2

1 À sin

2

sin

3

2

ð4-35jÞ

z

¼ 0 for plane stress ð4-35kÞ

z

¼ ð

x

À

y

Þ for plane strain ð4-35lÞ

xz

¼

yz

¼ 0 ð4-35mÞ

u

x

¼

K

II

2G

ffiffiffiffiffiffi

r

2

r

sin

2

þ 1 þ2 cos

2

2

ð4-35nÞ

u

y

¼À

K

II

2G

ffiffiffiffiffiffi

r

2

r

cos

2

À 1 À2 sin

2

2

ð4-35oÞ

xz

¼

K

III

ffiffiffiffiffiffiffi

2r

p

sin

2

ð4-35pÞ

yz

¼

K

III

ffiffiffiffiffiffiffi

2r

p

cos

2

ð4-35qÞ

u

z

¼

K

III

G

ffiffiffiffiffiffi

r

2

r

sin

2

ð4-35rÞ

w ¼ ¼ 0

K

I

¼

ffiffiffiffiffiffi

a

p

sec

a

2b

ð4-35sÞ

K

i

¼

ffiffiffiffiffiffi

a

p

1:12 À 0:61

a

b

þ 0:13

a

b

3

Â

1 À

a

b

À1=2

ð4-35tÞ

Particular Formula

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

4.27

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

The stress intensity factor for the plate with a single

edge crack, according to Gross, Srawley and Brown

(Fig. 4-27c).

The stress intensity factor for single edged cracked

plate/specimen subjected to bending (M

b

) (Fig.

4-27d).

Stress intensity factor for the case of angled

crack (Fig. 4-27A):

FIGURE 4-27A Through crack in an infinite plate for the

general case where the crack plane is inclined at 908 À

angle from the applied normal stress acting at infinity.

The stress intensity factors for Modes I and II.

K

I

¼

ffiffiffiffiffiffi

a

p

1:12 À 0:23

a

b

þ 10:6

a

b

2

À 21:7

a

b

3

þ 30:4

a

b

4

ð4-35uÞ

K

I

¼

ffiffiffiffiffiffi

a

p

1:112 À 1:40

a

b

þ 7:33

a

b

2

À 13:08

a

b

3

þ 14:0

a

b

4

ð4-35vÞ

K

I

¼ K

Ið0Þ

cos

2

ð4-36aÞ

K

II

¼ K

Ið0Þ

cos sin ð4-36bÞ

where K

Ið0Þ

is the Mode I stress intensity factor when

¼ 0

FIGURE 4-27a

FIGURE 4-27b

FIGURE 4-27c

FIGURE 4-27d

Particular Formula

4.28 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

Equations for stress and displacement

components in terms of polar coordinates:

The localized stress components at the vicinity of

Mode I crack tips in terms of polar coordinates.

The crack tip displacement fields for ‘‘first mode’’

(Mode I) in case of linear elastic, isotropic materials.

The localized stress components at the vicinity of

Mode II crack tip in terms of polar coordinates.

The crack tip displacement fields for Mode II.

r

¼

K

I

4

ffiffiffiffiffiffiffi

2r

p

5 cos

2

À cos

3

2

ð4-36cÞ

¼

K

I

4

ffiffiffiffiffiffiffi

2r

p

3 cos

2

þ cos

3

2

ð4-36dÞ

r

¼

K

I

4

ffiffiffiffiffiffiffi

2r

p

sin

2

þ sin

3

2

ð4-36eÞ

z

¼

1

ð

r

þ

Þð4-36f Þ

where

1

¼ 0 for plane stress and

1

is Poisson’s ratio,

, for plane strain. These singular fields only apply as

r ! 0.

u

r

¼

K

I

2E

ffiffiffiffiffiffi

r

2

r

ð1 þ Þ

ð2 À 1Þcos

2

À cos

3

2

ð4-36gÞ

u

¼

K

I

2E

ffiffiffiffiffiffi

r

2

r

ð1 þ Þ

Àð2 À 1Þsin

2

þ sin

3

2

ð4-36hÞ

u

z

¼À

2

z

E

ð

r

þ

0

Þð4-36iÞ

where

¼

3 À

1 þ

,

1

¼ 0, and

2

¼ for plane stress

¼ð3 À 4Þ,

1

¼ , and

2

¼ 0 for plain strain

K

I

is given by Eq. (4-36a).

r

¼

K

II

ffiffiffiffiffiffiffi

2r

p

sin

2

1 À 3 sin

2

2

ð4-36jÞ

¼

3K

II

ffiffiffiffiffiffiffi

2r

p

sin

2

cos

2

2

ð4-36kÞ

u

r

¼

K

II

2E

ffiffiffiffiffiffi

r

2

r

ð1 þ Þ

Àð2 À 1Þsin

2

þ 3 sin

3

2

ð4-36lÞ

u

¼

K

II

2E

ffiffiffiffiffiffi

r

2

r

ð1 þ Þ

Àð2 À 1Þcos

2

þ 3 cos

3

2

ð4-36mÞ

Particular Formula

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

4.29

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

The localized stress components and crack tip dis-

placement fields for Mode III in terms of polar

coordinates.

The critical applied tensile stress necessary for crack

extension according to Griffith theory for brittle

metals.

The modified Griffith’s equation for a small amount

of plastic deformation according to Orowan which

can be applied to ductile materials at low tem-

perature, high strain rate and localized geometric

constraint.

The elastic energy release rate for Mode I.

The elastic energy release rate for Mode II.

The elastic energy release rate for Mode III.

The stress-intensity factor for a centrally located

straight crack in an infinite plate subjected to uniform

shear stress .

The stress-intensity magnification factor for a cen-

trally located straight crack of length 2a in a flat

plate whose length 2h and width 2b are very large

compared with the crack length subjected to uniform

uniaxial tensile stress .

For stress-intensity magnification factors of plates

with straight crack located at various positions in

the plate and cylinders subjected to various types of

rate of loadings and for various values of a=b, a=d,

a=h, a=ðr

o

À r

i

Þ, and other ratios.

The factor of safety.

r

¼

K

III

ffiffiffiffiffiffiffi

2r

p

sin

2

ð4-36nÞ

¼

K

III

ffiffiffiffiffiffiffi

2r

p

cos

2

ð4-36pÞ

u

z

¼

2K

III

G

ffiffiffiffiffiffi

r

2

r

sin

2

ð4-36qÞ

c

/

ffiffiffiffiffiffiffiffi

EU

a

r

ð4-36rÞ

where

c

¼ critical applied stress

E ¼ Young’s modulus

U ¼ surface energy per unit area

a ¼ crack length.

¼

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

EðU þ pÞ

a

r

ð4-36sÞ

where p ¼ plastic deformation energy per unit area

for metallic solid, p ) U.

G

I

¼

1 À

2

E

K

2

I

for plane strain ð4-36tÞ

¼ K

2

I

=E for plane stress ð4-36uÞ

G

II

¼

ð1 À

2

Þ

E

K

2

II

ð4-36vÞ

G

III

¼

ð1 þ Þ

E

K

2

III

ð4-36wÞ

K

I

À iK

II

¼Ài

ffiffiffi

p

ffiffiffi

a

p

ð4-37aÞ

MF ¼

K

I

ffiffiffi

p

ffiffiffi

a

p

ð4-37bÞ

Refer to Figs. from 4-28, 4-29 to 4-34.

n ¼

K

Ic

K

ð4-38Þ

Particular Formula

4.30 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

FIGURE 4-28 Stress intensity magnification factor

K

I

=

ffiffiffi

p

ffiffiffi

a

p

for various ratios a=b of a flat plate with a cen-

trally located straight crack under the action of uniform uni-

axial tensile stress .

FIGURE 4-30 Stress intensity magnification factor

K

I

=

ffiffiffi

p

ffiffiffi

a

p

for an edge straight crack in a flat plate subjected

to uniform uniaxial tensile stress for solid curves there are

no constraints to bending; the dashed curve was obtained

with bending constraints added.

FIGURE 4-29 Stress intensity magnification factor

K

I

=

ffiffiffi

p

ffiffiffi

a

p

for an off-center straight crack in a flat plate sub-

jected to uniform unidirectional tensile stress ; solid curves

are for the crack tip at A; dashed curves for tip at B.

FIGURE 4-31 Stress intensity magnification factor

K

I

=

ffiffiffi

p

ffiffiffi

a

p

for a rectangular cross-sectional beam subjected

to bending M

b

.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

4.31

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

FIGURE 4-32 Stress intensity magnification factor

K

I

=

ffiffiffi

p

ffiffiffi

a

p

for a flat plate with a centrally located circular

hole with two straight cracks under uniform uniaxial tensile

stress .

FIGURE 4-33 Stress intensity magnification factor

K

I

=

ffiffiffi

p

ffiffiffi

a

p

for axially tensile loaded cylinder with a radial

crack of a depth extending completely around the circumfer-

ence of the cylinder.

FIGURE 4-34 Stress intensity magnification factor K

I

=

ffiffiffi

p

ffiffiffi

a

p

for a cylinder subjected to internal pressure p

i

having a radial

crack in the longitudinal direction of depth a. Use equation of tangential stress of thick cylinder subjected to internal pressure to

calculate the stress

at r ¼ r

o

.

4.32 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

Critical crack length

For values of critical stress-intensity factor (K

Ic

) for

some engineering materials.

REFERENCES

1. Lingaiah, K., Solution of an Asymmetrically Reinforced Circular Cut-out in a Flat Plate Subjected to

Uniform Unidirectional Stress, Ph.D. Thesis, Department of Mechanical Engineering, University of

Saskatchewan, Saskatoon, Sask., Canada, 1965.

2. Lingaiah, K., W. P. T. North, and J. B. Mantle, ‘‘Photoelastic Analysis of an Asymmetrically Reinforced

Circular Cut-out in a Flat Plate Subjected to Uniform Unidirectional Stress,’’ Proc. SESA, Vol. 23, No. 2

(1966), p. 617.

3. Peterson, R. E., ‘‘Design Factors for Stress Concentration,’’ Machine Design, Vol. 23, No. 27, Pentagon Pub-

lishing, Cleveland, Ohio, 1951.

4. Lingaiah, K., ‘‘Effect of Contact Stress on Fatigue Strength of Gears,’’ M.Tech. Thesis, Indian Institute of

Technology, Kharagpur, India, 1958.

5. Lingaiah, K., ‘‘Photoelastic Stress Analysis of Gear Teeth Under Load,’’ Department of Mechanical

Engineering, University Visveswaraya College of Engineering, Bangalore University, Bangalore, 1980.

6. Lingaiah, K., and B. R. Narayana Iyengar, Machine Design Data Handbook, Vol. I (SI and Customary Metric

Units), Suma Publishers, Bangalore, India, 1986.

7. Lingaiah, K., Machine Design Data Handbook, Vol. II (SI and Customary Metric Units), Suma Publishers,

Bangalore, India, 1986.

a

c

¼

1

K

Ic

sy

=2

2

Refer to Table 4-10.

Particular Formula

TABLE 4-10

Plane-strain fracture toughness or stress intensity factor K

Ic

for some engineering materials

Material K

Ic

Yield strength,

xy

Critical crack length, a

c

Previous designation UNS designation MPa

ffiffiffiffi

m

p

kpsi

ffiffiffiffi

in

p

MPa kpsi mm in

Aluminum

2014-T651 24.2 22 455 66 3.6 0.14

2024-T851 A92024-T851 26 24 455 66 4.3 0.17

7075-T651 A97075-T651 24 22 495 72 3.0 0.12

7178 13 30 490 71 5.8 0.23

Titanium

Ti-6Al-4V R56401 115 105 910 132 20.5 0.81

Ti-6Al-4V

Ã

R56401

Ã

55 50 1035 150 3.6 0.14

Steel

4340 G43400 99 90 860 125 16.8 0.66

4340

Ã

G43400

Ã

60 55 1515 220 2 0.08

H-11 – 38.5 35 1790 260 <0.6 <0.02

H-11 – 27.8 27 2070 300 0.23 0.009

52100 G52986 14 13 2070 300 <0.06 <0.002

Ã

Heat treated to a higher strength.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS 4.33

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

8. Lingaiah, K., Machine Design Data Handbook (SI and Customary US Units), McGraw-Hill Publishing Com-

pany, New York, 1994.

9. Aidad, T., and Y. Terauchi, ‘‘On the Bending Stress in a Spur Gear,’’ 3 Reports, Bull. JSME, Vol. 5 (1962),

p. 161.

10. Dolan, T. J., and E. L. Broghamer, ‘‘A Photoelastic Study of Stresses in Gear Tooth Fillets,’’ Univ. Illinois

Exptl. Station. Bull., 335 (1942).

11. Hetenyi, M., The Application of Hardening Resins in Three-Dimensional Photoelastic Studies, J. Appl. Phys.,

Vol. 10 (1939), p. 295.

12. Shigley, J. E., and L. D. Mitchell, Mechanical Engineering Design, McGraw-Hill Publishing Company, New

York, 1983.

13. Greenhood, D. C., Engineering Data for Production Design, McGraw-Hill Publishing Company, New York,

1961.

14. Carlson, R. L., and G. A. Kardomateas, An Introduction to Fatigue in Metals and Composites.

15. Anderson, T. L., Fracture Mechanics—Fundamentals and Application, 2nd edition, CRC Press, New York,

1995.

16. Fedderson, C., ‘‘Discussion’’, in Plane Strain Crank Toughness Testing of High Strength Metallic Materials,

ASTM STP410, American Society for Testing Materials, Philadelphia (1967), p. 77.

17. Keer, L. M., and J. M. Freedman, ‘‘Tensile Strip with Edge Cracks,’’ Int. J. Engineering Science, Vol. 11

(1973), pp. 1965–1075.

18. Gross, B., and J. E. Srawley, ‘‘Stress Intensity Factors for Bend and Compact Specimens,’’ Engineering

Fracture Mechanics, Vol. 4 (1972), pp. 587–589.

19. Gross, B., J. E. Srawley, and W. E. Brown Jr., Stress Intensity Factors for a Single Edge Notch Tension

Specimen by a Boundary Collocation of a Stress Function, NASA Technical Note D-2395, 1964.

20. Damage Tolerant Design Handbook, MICIC-HB-01, Air Force Materials Laboratory, Wright-Patterson Air

Force Base, Ohio, December 1972, and supplements.

4.34 CHAPTER FOUR

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS CONCENTRATION AND STRESS INTENSITY IN MACHINE MEMBERS

CHAPTER

5

DESIGN OF MACHINE ELEMENTS

FOR STRENGTH

SYMBOLS

5;6

A area of cross-section, m

2

(in

2

)

b a shape factor (b > 0)

B a constant

e

sz

size coefficient

e

s

surface coefficient in case of tension and bending

e

0

s

surface coefficient in case of torsion

E Young’s modulus, GPa (Mpsi)

F normal load (also with suffixes and primes), kN (lbf)

F

0

m

static equivalent of cyclic load, kN (lbf)

G modulus of rigidity, GPa (Mpsi)

h thickness, m (in)

K

sz

size factor

K

s

surface factor

K

theoretical normal stress-concentration factor

K

theoretical shear stress-concentration factor

K

f

fatigue normal stress-concentration factor

K

f

fatigue shear stress-concentration factor

M

b

bending moment (also with suffixes and primes), N m (lbf in)

M

0

bm

static equivalent of cyclic bending moment, N m (lbf in)

M

t

twisting moment (also with suffixes and primes), N m (lbf in)

M

0

tm

static equivalent of cyclic twisting moment, N m (lbf in)

n safety factor

a constant

n

a

actual safety factor (also with suffixes)

n

d

design safety factor (also with suffixes)

q index of sensitivity

q

f

index of notch sensitivity for alternating stresses

r notch radius, mm (in)

t time, h

x

0

the guaranteed value of x (x

0

! 0)

y

max

maximum deflection

Z

b

flexural section modulus, m

3

or cm

3

(in

3

)

Z

t

polar section modulus, m

3

or cm

3

(in

3

)

characteristic or scale value ( ! x

0

)

5.1

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

Source: MACHINE DESIGN DATABOOK

normal stress (also with suffixes and primes), MPa (psi)

0

initial stress, MPa (psi)

su

ultimate strength, MPa (psi)

e

elastic limit for standard specimen for 12.5 mm (

1

2

in), MPa (psi)

d

design stress (also with suffixes), MPa (psi)

x

normal stress in x direction, MPa (psi)

y

yield stress, MPa (psi)

normal stress in y direction, MPa (psi)

nom

nominal normal stress, MPa (psi)

max

maximum normal stress, MPa (psi)

0

e

elastic limit for any thickness h between 12.5 mm (

1

2

in) and

75 mm (3 in), MPa (psi)

00

e

elastic limit for 75 mm (3 in) specimen, MPa (psi)

fb

endurance limit in bending, MPa (psi)

shear stress (also with suffixes and primes), MPa (psi)

e

elastic limit in shear, MPa (psi)

sy

yield strength in shear, MPa (psi)

xy

shear stress in xy plane, MPa (psi)

nom

nominal shear stress, MPa (psi)

f

endurance limit in torsion, MPa (psi)

" engineering or average strain, mm/m (min/in)

"

0

true strain, mm/m (min/in)

"

t

total creep, after a time t, mm/m (min/in)

"

0

initial creep, mm/m (min/in)

_

"" creep rate (m/m)/h [(min/in)/h]

v

0

a constant

Suffixes for

s static strength (

u

or

y

)

u ultimate strength

y yield strength

e elastic limit

a amplitude

b bending

m mean

t tension

max maximum

min minimum

f endurance limit (also used for reversed cycle)

o endurance limit repeated cycle

Primes for

0

(single) static equivalent

00

(double) combined stress

5.2 CHAPTER FIVE

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

DESIGN OF MACHINE ELEMENTS FOR STRENGTH

STATIC LOADS

Influence of size

The size coefficient (Fig. 5-1, Fig. 5-2, and Table 5-1)

e

sz

¼ 1 À0:016

1 À

00

e

e

ðh À 12:5Þð5-1Þ

where

e

¼ elastic limit for 12.5 mm (0.5 in)

00

e

¼ elastic limit for 75 mm (3.0 in)

Particular Formula

TABLE 5-1

Strength ratios of various materials for use in Eqs. (5-1) and (5-2)

Values of

00

e

=

e

Material Natural state Annealed

Drawn at

6508C

Drawn at

5358C

Drawn at

4258C

Aluminum, strong, wrought 0.93 — — — —

Tobin bronze 0.90 — — — —

Monel metal, forged 0.80 — — — —

Ductile iron 0.80 0.98 — — —

Low-carbon steel, C < 0:20% 0.84 — — — —

Medium-carbon steel, 0.30 to 0.50% C — 0.85 0.72 0.59 0.53

Nickel steel, SAE 2340 — 0.86 0.80 0.74 —

Cr–Ni steel, SAE 3140 — 0.86 0.75 0.70 0.65

Cast iron, Class no. 20 0.55 — — — —

Cast iron, Class no. 25 0.73 — — —

Cast iron, Class no. 35 0.60 — — —

Wrought iron 0.55 — — —

FIGURE 5-1 Change of elastic limit

with size of section.

FIGURE 5-2 Influence of size on elastic limits.

DESIGN OF MACHINE ELEMENTS FOR STRENGTH

5.3

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

DESIGN OF MACHINE ELEMENTS FOR STRENGTH

The size factor

The relation between size coefficient and size factor

The elastic limit for any thickness h between 12.5 mm

and 75 mm can be determined from the relation (Fig.

5-1)

INDEX OF SENSITIVITY

The index of sensitivity

The actual or real stress-concentration factor

SURFACE CONDITION (Fig. 5-3)

The surface factor for the case of tension and bending

The surface coefficient in case of torsion

K

sz

¼

250

300 À 4h þ

00

e

e

ð4h À 50Þ

ð5-2Þ

e

sz

¼

1

k

sz

ð5-3Þ

00

e

¼

e

À

ð

e

À

00

e

Þðh À 12:5Þ

ð75 À 12:5Þ

ð5-4Þ

q ¼

K

a

À 1

K

À 1

ð5-5Þ

K

a

¼ 1 þqðK

À 1Þð5-6Þ

K

s

¼

1

e

s

ð5-7Þ

e

0

s

¼ 0:425 þ0:575e

s

ð5-8Þ

Particular Formula

FIGURE 5-3 Reciprocals of stress-concentration factors caused by surface conditions.

5.4 CHAPTER FIVE

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

DESIGN OF MACHINE ELEMENTS FOR STRENGTH